Power - Wind Power Testing at UNAVCO through 2005, Phase 3

Wind Power Testing at UNAVCO through 2005, Phase 3

|

Status as of 6 Nov 2002: The wind system is up, running and charging, but not generating as much power as before. We are investigating. |

The University of Colorado Mountain Research Station Tundra Lab, located at the "Saddle" on Niwot Ridge is the perfect testing grounds to examine extreme weather conditions for the wind power unit. This 11,600 FT. station experiences a January mean temperature of -13.2 degrees Celsius as well as constant winter winds and gusts up to and above 100 mph, which should be an excellent test of exactly how "Maintenance Free" this unit really is. |

Configuration

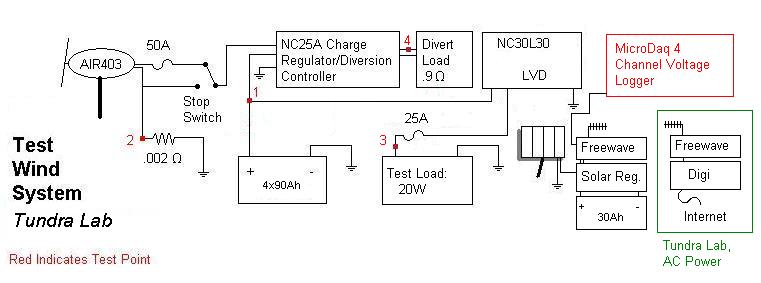

This site serves as a test site for our power, GPS and communications equipment. The configuration during the test includes:

Load

20W dummy load

Power Source:

1 Southwest Wind Power Air Industrial Generator on 14’ tower; 1x20"rebar w/ welded on closed links.

1 55W solar panel (to power freewave radio independant of wind system)

Power Regulation:

1 Flexcharge NC25A diversion controller - to control wind system

1 Flexcharge NC30L30 solar controller w/ LVD - Only LVD is used for dummy load

1 SunSaver 6 solar controller w/ LVD - For Freewave system

Batteries:

4 90A/hour deep cycle batteries for wind system

1 30A/hour battery for freewave system

Data Logging:

1 MicroDaq 4-channel data logger - self powered

Enclosure:

JOBOX: Model 652990 - 36x17x19.5 16 guage steel storage chest

Log

| 4 Oct 2002: | Tower and blade failure. |

| 15 Oct 2002: | System is repaired. |

| 6 Nov 2002: | Data, Oct 16-Nov 6 |

| 21 Apr 2003: | System failure and moving on... |

4 Oct 2002: Tower and blade failure.

|

|

On October 4, 16 days into the testing, the wind system tower was observed via web cam to be tilted severely. An emergency repair trip was scheduled for the morning of October 5. We had speculated that one of the stakes for the supporting cables had failed. Upon arrival, we found that this was not the case, rather, the base coupler had shifted to the end of the base. The entire structure was shaking violently, as winds were a constant 40-60 MPH. Upon stopping the generator from spinning, we found one of the blades had broken off. The question at hand was: Did the blades break off as a result of the tower shifting or did the tower shift as a result of the blade breaking off? After analyzing the data (see below), it appears that at 23:00 on October 3, there was an immediate dropoff in current generated by the generator with no other gradual or immediate changes. This event coincides with a 65 MPH gust measured at the MRS Lab, which is located approximately 1000 yards North West, and does not exerience as powerful of winds as the wind site does. Is is speculated from this data that a large gust caused a blade to fail, which in turn put the system out of balance and caused the base to shift. As a result of the maintenance trip, the following issues will be addressed:

|

Wind Data

Pictures: (right-click and select "View Image" to enlarge)

15 Oct 2002: System is repaired.

|

|

On 14 October we returned to the site with a new set of blades and sealed load box. The system was put back up with all the additional rigging from the last trip and the guy wires were pulled extremely tight. As an added bonus, the shape of the ground allowed us to erect the tower with static tension INTO the wind. The result was an extremely tight tower that can not wiggle or vibrate nearly as much as the initial setup. The new load box is a sealed cast steel box with two ceramic power resistors that are mounted onto hollow aluminum tubes that protrude 5" out each end of the box, allowing heat to easily dissipate, but keep moisture out. In addition, we used thicker weatherstripping on the equipment box and used a cam strap to tighten it shut. The result was an extremely solid system that is VERY quiet. The initial setup could be heard in strong winds from about 3 miles away. We could not hear this system more than 50 ft. away. Vibrations in the tower and wires are minimal and the blades/unit appear to track very straight. See the pictures below. Data update - 21 October 2002: The first several days of data are shown below and the results don’t look good. Power levels from the generator are extremely low, especially when compared to the first three weeks (above: Wind System Data - Tundra Lab - Sept 18-Oct 7). Investigation is underway, however, it appears that the system is still functional, even under the lower power. |

Pictures: (right-click and select "View Image" to enlarge)

|

Shad O’Neel seals the equipment box. |

The tower base is rigged with large rocks for stability. |

|

The diversion load was replaced with a sealed unit. |

Each of the stakes were weighted down with rocks. |

6 Nov 2002: Data, Oct 16-Nov 6

21 Apr 2003: System failure and moving on...

21 April 2003 - Though we suffered many hurdles in Phase 3 of the wind generator testing, we learned many lessons. These findings will be presented shortly. Still recognizing the value wind power can play in the ability for UNAVCO to provide alternative power to remote DC stations, a new AirX unit has been purchased. Featured in this unit is an internal regulator with overspeed braking. We hope to prove with our deployment of this unit at the Marshall test site that ease of installation will greatly improve the overall reliability of these units in a remote location. More information on this deployment will be available when Phase 4 begins.

Send questions or comments about this page to Support (support![]() unavco.org).

unavco.org).

)